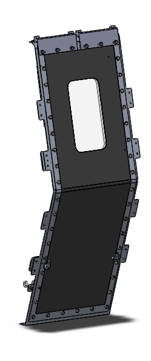

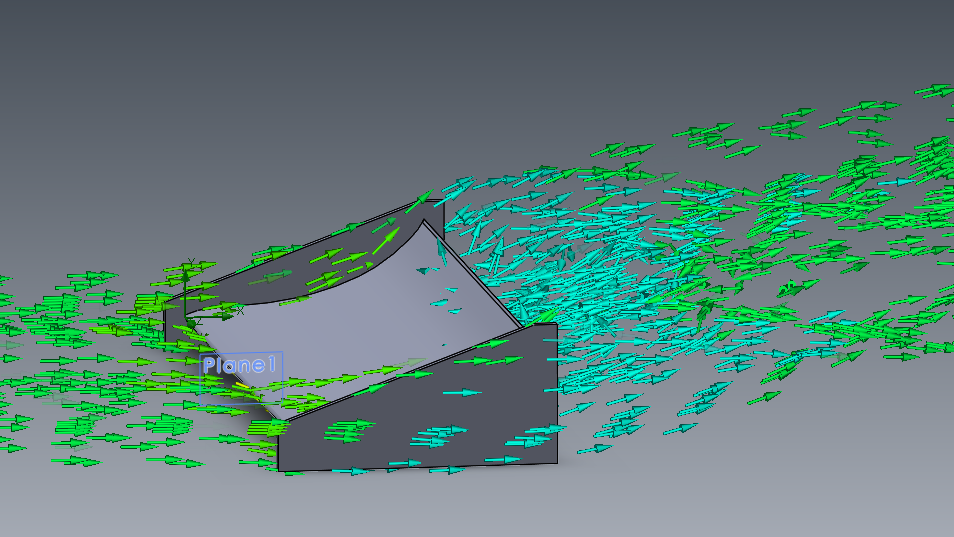

Designed aluminum frame optimized for structural rigidity using FEA. Validated FEA using solid mechanics calculations to measure for shear failure. Later optimized for weight – removing over 40% of material with same rigidity.

As Communications Liaison, I maintained constant contact with the client and any other external stakeholders for transfer of information. Doing so allowed me to gain valuable skills in professional communication.

Overcame unorthodox cabin geometries by developing custom hinges, support mechanisms, and brackets for seamless connection between door and cabin. Custom parts were generated with machining in mind.

Decided to use two gas spring pistons to assist in opening of the door. This ensures the door is kept open during loading or mid-flight operations, without manual assistance. Gas pistons and mounting locations were selected on the basis of calculations with an included factor of safety.

The Design Process