New Venture Design Course - PharmaBox

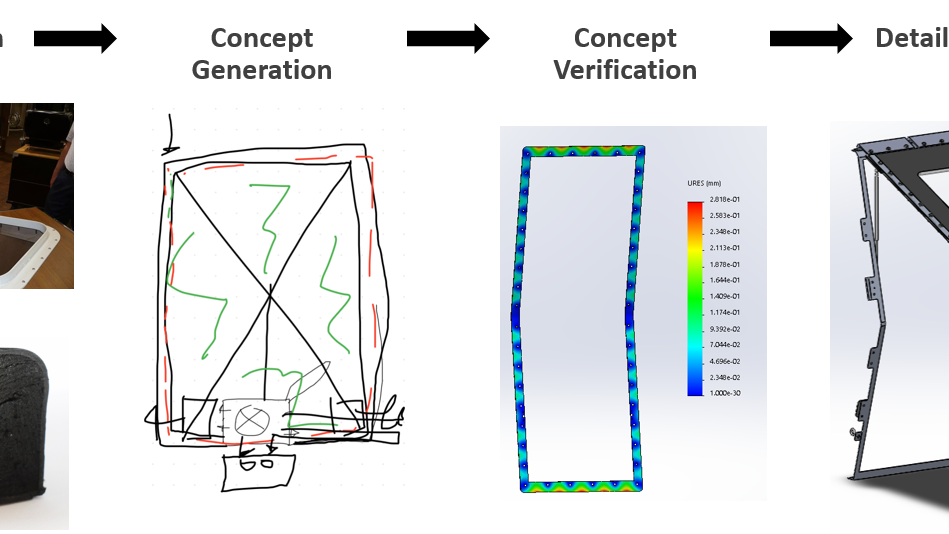

My capstone project of my final year in mechanical engineering involved the design of a device that can automatically fill customized blister packs for patients taking multiple prescription medications on a regular basis. This was done in the “New Venture Design” course where teams emulate a “start-up” environment by engaging in all aspects of product development – including both technical design and business planning. As the mechanical engineering on the project, I was tasked with developing the dispensing mechanism and the control system.

For further analysis including step-by-step design, further improvements, and verification and validation, click "Technical Report" below. For in-depth prototyping analysis, click "Prototyping Analysis" below:

As mentioned, PharmaBox is a device that can automatically fill customized blister packs for patients taking multiple prescription medications on a regular basis. By automating this process, it saves pharmacists the hassle of sending blister packs to central fill locations, or doing them by hand. Pharmabox allows for a quick, easy, and convenient way of filling blister packs at the pharmacy itself, requiring no user intervention once the desired pills are loaded into the machine.

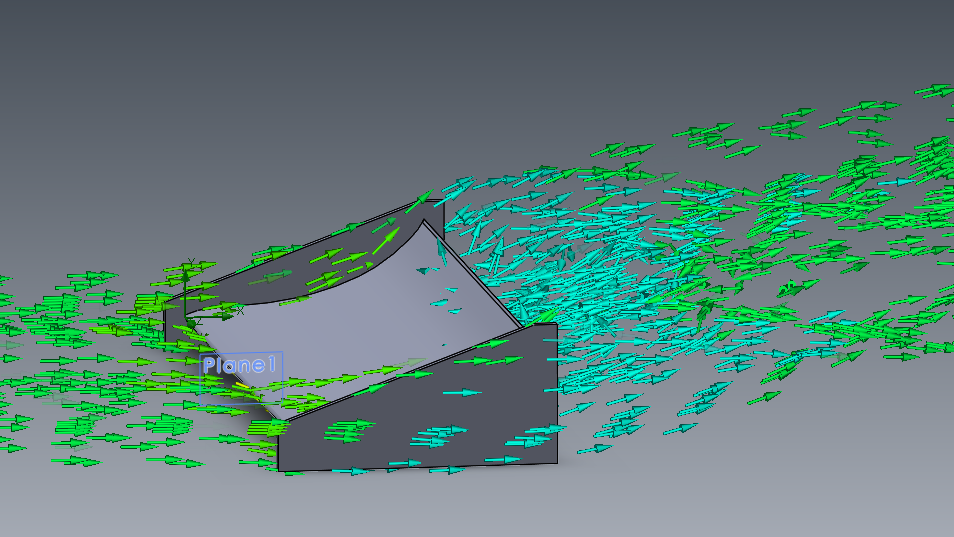

Once plugged in, the pharmacist would load each type of pill into one of the pill hoppers on the machine. The user would then input the desired frequencies of each pill type (once daily, twice daily, once per week, etc.) and run the machine. Starting with the first pill hopper, it moves with a belt and pulley system with stepper motors to position itself for dispensing. From here, it goes over a sample tray containing the empty blister pack, filling each pill into the correct pouch. Once the first pill hopper is finished, the second pill hopper then moves to dispense its pills, repeating this process until all pill types have been dispensed. Once this process ends, the packs are quickly closed and sealed, and the job is done.

Product Demonstration Video