As a Co-op Mechanical Product Designer, I was trusted with undertaking important and costly tasks involving design, testing, and research on existing products, as well as performing R&D validation on potentially lucrative products.

View various projects below

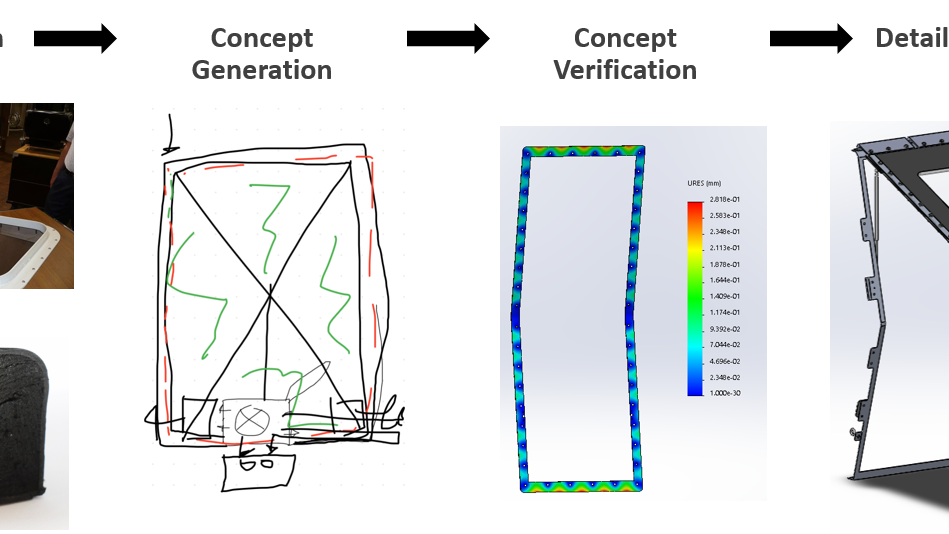

IMPACT TEST

The scope of this project was to independently design an impact test to evaluate the strength of certain powder metal parts. I gathered information and expectations, defined the needs of the project, and brainstormed in a process to plan my design. During the early stages of development, I created prototypes to get a sense of energy required to fracture the piece. I rapid tested these prototypes to create an effective final product. Then, I designed the testing rig in CREO, made accompanying engineering drawings, and sent them to an external manufacturer. Further modifications needed to be made when I acquired the components, and I was able to do so using the in-house milling machine, drill press, and bench grinder. My testing rig is currently being used by the company to evaluate powder metal shipments. This project enhanced my understanding of principles of design and analysis – with a focus on manufacturing – and taught me to create professional engineering drawings and specifications.

Testing Rig

Above is a testing rig meant for a pre-study to a main-focus R&D project set out by the company. I was tasked with creating professional engineering drawings for the assembly. Further, I set out to contact external vendors to manufacture the rig, and maintained communication with them to ensure clarity in the design.